Home > Ag-Paste > EO-S 2450U

| T | EO tech | ||

|---|---|---|---|

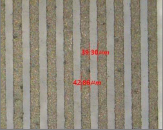

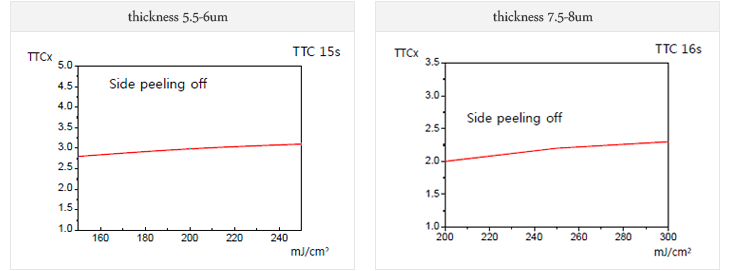

| Development - Margin | #400 Mesh 5-6㎛ |

≤TTC x 1.8 (150mJ/cm2) |

≤TTC x 2.8 (150mJ/cm2) |

| #325 Mesh 7-7.5㎛ |

≤TTC 1.3 (250mJ/cm2) |

≤TTC 2.2 (250mJ/cm2) |

|

| The time to reach 100μΩ∙cm at 140℃ | ≥50min | ≥30min | |

| TDS data | |||

| Contents | Conditions | Details |

|---|---|---|

| Printing | • SUS #400 (Emulsion 10㎛) • Squeeze pressue 0.2Mpa |

Before exposure →6.4±0.8㎛ • Snap Off 1.5mm |

| Printed material | • V270LTFMD5 (ITO -side) • OFSD5 (Etching -side) |

|

| Pre Dry | • 88 90℃, 10min | • Heat Circulating Oven |

| Exposure | • 150mJ/cm2 | • 17mW/cm2 |

| Develop | • Na2CO3 Solution 0.2wt% (30℃) in DI Water |

• Pressure 0.3MPa |

| Post Curing | • 140℃ 30min (Oven) | • Heat Circulating Oven |

| Contents | Results | |

|---|---|---|

| Physical Property |

Color | Silver Gray |

| Silver content | 75.3 % | |

| Non volatile | 87.6 % | |

| Viscosity (cps) (10rpm, 25℃) |

16,000 | |

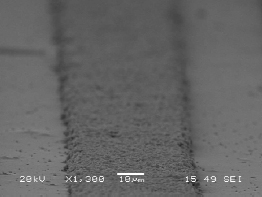

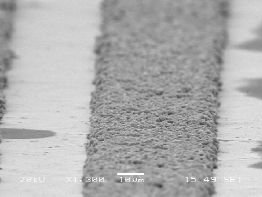

| After test on ITO etching side |

Resistance(mΩ/□) (두께 6-6.5㎛) |

• 130-150 mΩ/□ (On Etching side of OFSD5) • 115 125 mΩ/□ (On ITO Side V270LTFMD5) |

| Thickness before exposure(㎛) | 6.4±0.8㎛ (SUS #400) | |

| Adhesion | 3M 610 Taping 5B | |

| Humidity Test 8 5℃ 85% 500h |

3M 610 Taping 4B | |

| Hardness | 2H 750g | |

| 23℃ 3Days | • Change Rate of viscosity <±10% • Change Rate of Sheet resistance <±10% |

|

| Contents | ITO side | ITO Etching side |

|---|---|---|

| TTC | 15s | 15s |

| 현상시간 | 35 (≥TTC 2 ) | 35 (≥TTC 2 ) |

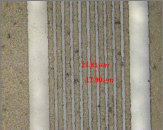

| 20/20(㎛) |  |

|

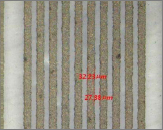

| 30/30(㎛) |  |

|

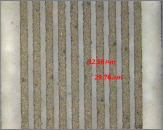

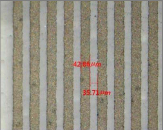

| 40/40(㎛) |  |

|

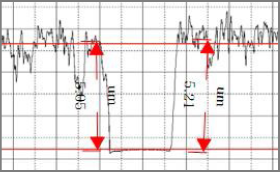

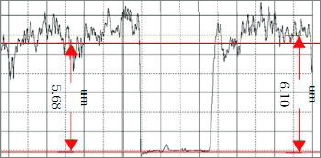

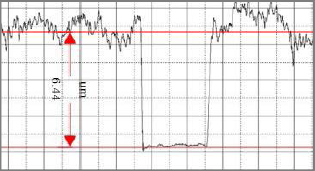

| SQ Speed(mm/s) | spl_1 (10rpm 19kcps) (Ave.) |

|---|---|

| 39.06 | 5.04 ㎛  |

| 73.31 | 5.85 ㎛ |

| 90.91 | 6.53 ㎛ |

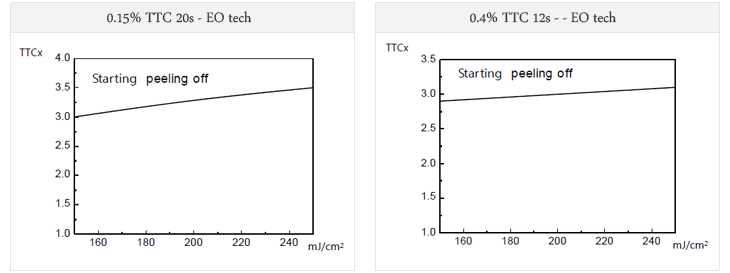

| 0.15% TTC 20s | |||

|---|---|---|---|

| 150mJ/cm2 | X1.5 No peeling |

X2 No peeling |

X3.0 Peeling off |

| 200mJ/cm2 | X1.5 No peeling |

X2 No peeling |

X3.3 Peeling off |

| 250mJ/cm2 | X1.5 No peeling |

X2 No peeling |

X3.5 Peeling off |

| 0.4% TTC 12s | |||

|---|---|---|---|

| 150mJ/cm2 | X1.5 No peeling |

X2 No peeling |

X2.9 Peeling off |

| 200mJ/cm2 | X1.5 No peeling |

X2 No peeling |

X3.0 Peeling off |

| 250mJ/cm2 | X1.5 No peeling |

X2 No peeling |

X3.1 Peeling off |

| Condition | On Etching side | |

|---|---|---|

| Adhesion 3M 610 Taping | 0회 |  |

| 10회(5B) |  |

|

| Hardness Test(2H) | 750g |  |

| Adhesion 3M 610 Taping | 85℃ 85% 500hr | 4B |

|

||